2024-06-03

2024-06-03

CNC machining is revolutionizing the automotive industry by enabling fast and precise customization. In this post, we'll discuss the benefits, applications, and how to choose the right CNC machining partner for your automotive manufacturing needs.

Benefits of CNC Machining in Automotive Parts Customization:

1. Speed and Efficiency: CNC machining allows for rapid production of automotive components, reducing lead times and meeting market demands more effectively.

2. Precision and Accuracy:With CNC machining, automotive parts can be manufactured with high precision and accuracy, ensuring consistent quality and superior performance.

3. Design Flexibility: CNC machining offers unparalleled design flexibility, allowing for the creation of complex and customized automotive parts.

4. Cost-Effectiveness: While initial investments may be required, CNC machining offers long-term cost savings through reduced labor costs, minimized material waste, and optimized production efficiency.

Applications of CNC Machining in the Automotive Industry:

CNC machining finds diverse applications in automotive parts customization, including:

1. Engine Components: CNC machining plays a vital role in manufacturing engine components such as cylinder heads, pistons, and intake manifolds, ensuring precise specifications and enhanced performance.

2. Interior and Exterior Parts: From dashboard panels to door handles, CNC machining enables the production of aesthetically pleasing and functionally superior interior and exterior components.

3. Braking Systems: CNC machining is instrumental in manufacturing critical parts of braking systems, such as brake calipers and rotors, ensuring optimal performance and safety.

Choosing the Right CNC Machining Partner:

Selecting the right CNC machining partner is crucial for successful automotive parts customization. Consider the following factors:

1. Expertise and Experience: Look for a partner with extensive experience in the automotive industry and a proven track record of delivering high-quality CNC machined parts.

2. Technological Capabilities: Ensure that the machining partner has state-of-the-art CNC machines and equipment to meet your specific customization requirements.

3. Quality Control: Verify that the partner has robust quality control measures in place to ensure consistent and reliable product quality.

4. Project Management: A reliable CNC machining partner should possess strong project management capabilities, providing clear communication and efficient delivery.

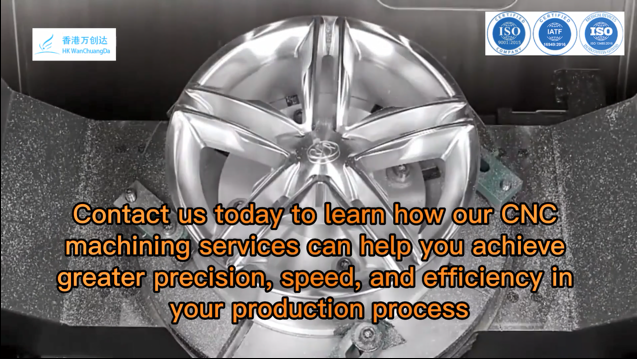

In conclusion, CNC machining is revolutionizing automotive parts customization, offering speed, precision, and design flexibility. By embracing this technology and choosing the right machining partner, automotive manufacturers can stay competitive and deliver innovative, customized products to meet customer demands effectively.